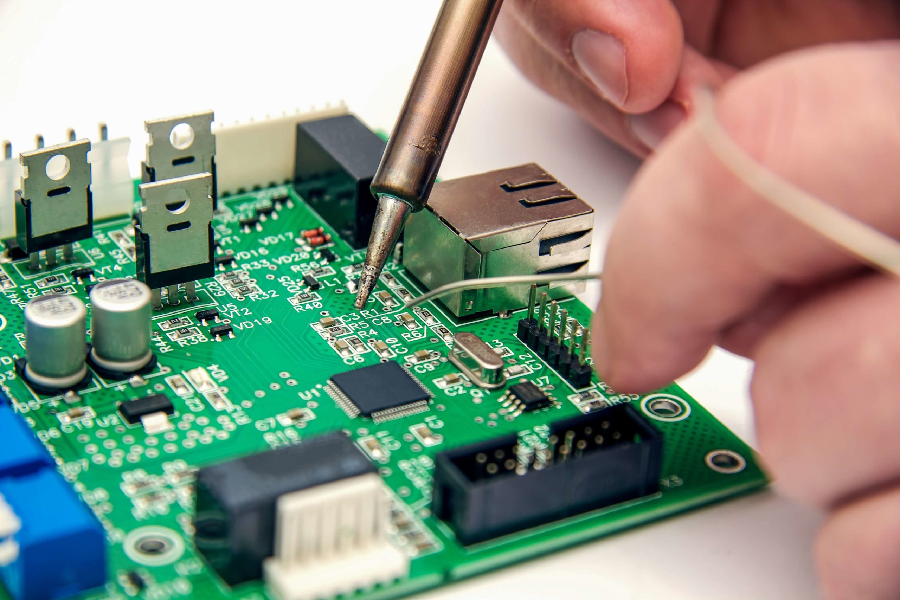

Electronics have become an indispensable part of everyday life. Everything from our mobile phones to our automobiles contains electrical parts. The printed circuit board, also known as a PCB, is at the heart of these electronics.

When most people see PCB, they recognize them. These are the little green chips with lines and copper parts found at the heart of gutted electronic devices. These boards are fiberglass, copper lines, and other metal parts and are held together with epoxy and insulated with a solder mask. This solder mask is responsible for the different green color.

Have you ever seen those boards with parts that are solidly adhered to them? Never consider them to be mere PCB board decorations. An advanced circuit board will not be functional until parts are mounted on it. An assembled PCB is a PCB with components mounted on it, and the manufacturing process is known as PCB assembly, or PCBA for short. Traces are copper lines on bare board that electrically connect connectors and components. They route signals between such features, enabling the circuit board to perform as intended. These features range from simple to complex, yet PCBs can be as small as a thumbnail.

The 3 main PCB types are as follows:

• Rigid PCB: The most popular PCB base, accounting for most PCBAs, is a rigid one. A rigid PCB’s solid core provides board rigidity and thickness. These rigid PCB foundations are made of a variety of materials. The most popular is fiberglass, also known as “FR4”. Less expensive PCBs are made from epoxies or phenolics, but they are less durable than FR4.

Flexible PCBs are a little more pliable than their more rigid counterparts. These PCBs are typically made of bendable, high-temperature plastic such as Kapton.

• Metal Core PCB: These boards are an additional option to the standard FR4 board. These boards, which have a metal core, spread heat more efficiently than others. This aids in heat dissipation and protects more heat-sensitive board parts.

PCB assembly is such a complex and technological process that numerous elements must be carefully considered, and even minor changes can significantly impact cost and product quality. This article’s descriptions of the PCB assembly process focus solely on standard PCBA procedures and technologies. Design files and customer specifications heavily influence the practical manufacturing process. As a result, customers must consider how to evaluate a dependable PCB assembler before placing their PCBA order.

Chinapcbone is the leading provider of PCB solutions. They can handle all of your PCB needs, from part sourcing to electronic assembly. They will be there for you every step, offering comprehensive expertise and quality assurance.

When you choose them as your cooperative PCBA company, you partner with a service that provides the best results. Their PCB assembly services adhere to the highest quality standards, including IPC Class 3, RoHS, and ISO 9001:2008 certification. Furthermore, they can handle any PCB, whether double-sided or single-sided, SMT, through-hole, or mixed-assembly. Whatever you need to be done, they can do it!

ChinaPCBOne Technology LTD. is the author of this article on PCB assembly. Find more information, about China PCB.