To ensure a friction-free linear motion, one can simply use Ball Splines which will ensure simultaneous transmission of torsional loads.

The outer shell that serves as a housing for balls in the ball spline is called a nut.

Each nut can be preloaded individually as it is manufactured so that rigidity is provided. Preloading the nut will increase the contact area while making sure that the direct loading capability restricts any radial movement. This way the overhung moemnt cababilities are increased to provide a sturdier structure for very heavy loads.

Ball splines from the company Tuli utilize the friction force through the contact of the steel ball within the spline nut and the grooves on the spline shaft

When you’re shopping for ball splines, certain specifications need to be met.

Overall shaft length – means the length intended for mounting. The ball nut will travel in a straight line alongside the inner race before it goes back to its original position.

Inner race length – means the groove, in which the balls of a bearing ride in.

The outer diameter of the spline shaft – is the largest diameter of the shaft.

The outer diameter of the spline nut – is the biggest outer diameter of the spline nut.

Static torque – a maximum load that can be applied to the ball nut, while it is stationary.

Dynamic torque – is the maximum capacity load that can be applied to the whole assembly.

The mounting of ball splines can be done in the following ways.

- with a pin or set screw

- using key and pin

- using square spline nut

- using geared flange spline nut

When you have low torque requirements, it is safe to use a pin or set screw. The key with a pin, on the other hand, is best used with high torque needs.

Other common features of ball splines include a hollow shaft with a hollow shaft inner bore diameter. If you’re looking to protect the environment while doing heavy work, check the operating temperature advised for ball splines.

Best solutions for linear guide

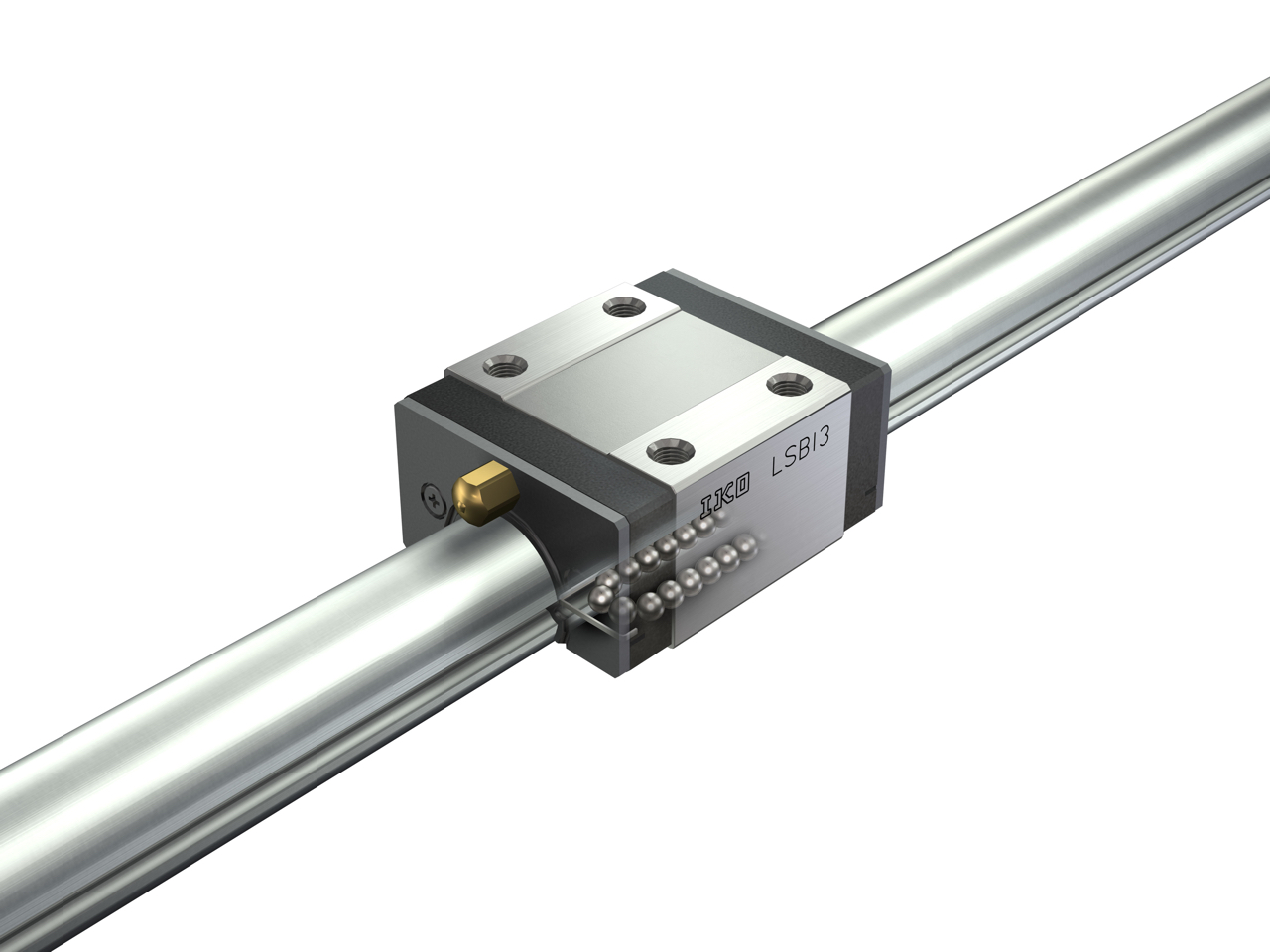

Linear guides, also known as linear rail slides are devices that support carrying loads and procure straight linear motion. They have two components – the sliding carriage and the rail or a guide. The carriage moves alongside the rail, all the while supporting the applied load.

A linear rail will be a better choice than a rod because the rail will ensure that the object doesn’t rotate while transmitting. To prevent rotation of the linear rod, you would have to double them up, which again makes the linear rail a better option. It will eliminate rotation while providing a lighter and simpler tool to use for high accuracy.

Most affordable and very high in quality linear rails come from Tuli, where you can find a solution for all your linear motion needs.